If you have implemented the recommendations from this column for the last year, then your business should be a cash-generating machine. You should be generating much more cash each day than you are burning. Life should be good!

In fact, life can be so good at this level that a lot of companies stop improving. They are really happy with where they are. They don’t think it can get any better. Yet, there is a whole other level of ‘better’ to be had for those who are willing to go for it.

This new level of ‘better’ enables your business to:

- Generate even more cash each day – without increasing sales

- Make even more profit and still have the same business volume

- Have the same number of customers, the same number of kitchens per day, and yet be even more profitable.

The foundation for making this work is continuously running your business using the recommendations from my six-article series (SRG Nov. 2020 through May 2021) on improving your business:

- You have a sound definition of your constraint

- You have a buffer management system that ensures your constraint is fed the required amount of Throughput Dollars ($T)

- You are continuously reducing the non-value-added activities in your business

- You have a smooth process for calculating the $T for every order

- You are scheduling enough $T each day to cover your operating expense and also generate a profit

- You have a daily management routine that focuses on increasing $T and delighting your customers.

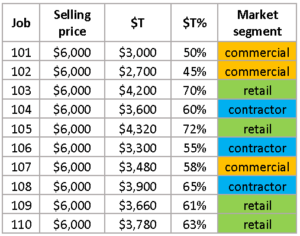

To reach this next level, we need to dive into the $T for a sampling of orders. This will help us begin to understand the factors that determine how fast your business makes money. Chart 1 (below) shows a list of 10 orders. Note that I have made the sales price for all the orders the same, but these aren’t the same kitchens. I’m just taking selling price out of the analysis to make the concepts clearer.

From this we can see that some jobs obviously have higher $T than others. Typical factors that impact that difference are:

- Market segment — retail, contractor, commercial

- Discount levels — different discount percentages for different customers

- Material type — granite, quartzite, porcelain, marble

- Salesperson — some sell on price and some sell features

- Kitchen configuration — miters, raised bar tops, full-height splashes.

However, $T per job is only part of the story of how fast your business generates cash.

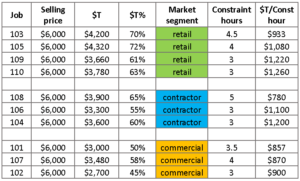

Since you have defined your constraint and are using the above tools to run your business, then we also need to look at how these jobs run through the constraint. Assuming Install is your constraint, Chart 2 shows the number of hours each job requires for travel and installation. We then divide the $T for each job by the number of hours on the Constraint to get $T per Constraint Hour.

Since the Constraint is the ultimate bottleneck in your business, we have just calculated how fast each job generates cash ($T) for your business.

CHART 1

CHART 2

Looking closely at the data, we see that there is still a lot of variability within each market segment.

- Retail runs from a low of $933/hour to a high of $1,260/hour

- Contractor runs from $780/hour to $1,200/hour

- Commercial runs from $857/hour to $900/hour.

While the drivers between market segments may be obvious, the drivers within segments may not. You will need to pull each order to see the job details so you can assess what is causing the difference. Typical factors are:

- How you price various materials: “Program” colors may be stocking colors that you sell by the square foot. “Non-program” colors may be special order, and you price them by the slab.

- Your contractor salesperson thinks they have to sell primarily on price and tends to offer more discounts.

- Some contractors run their business better than others. Some don’t care if the tile guys are in the kitchen when you show up to install. Others manage those conflicts much better.

- The kitchen designs in your area may feature waterfall islands, or raised bar tops, or full-height backsplashes, or they may be simpler designs without those features. Your practices may require two trips for full height splashes.

Beware: The differences in $T/hour may not look significant — the $T/hour for job 105 compared to job 110 may only be $180. However, when you multiply that by 8 hours a day x 5 days a week x 50 weeks a year, the difference is $360,000 per year.

That means, if you can find a way to fill your shop with jobs more like #110 and less like #105, you can make $360,000 more profit in a year – running the same number of kitchens per day through your shop, with the same people, with the same machines, working the same hours!

Remember, this is from simply replacing one #105 job per day with one #110 job per day. Think what could happen if you could replace all your low $T/hour jobs with high $T/hour jobs! This jump in profit is simply from understanding what factors determine how fast you generate cash.

We spent the past year talking about ways that you can increase the amount of money your business can make. This article shows you how to accelerate the rate at which your business makes money. If you robustly implement the fundamentals from the earlier articles and apply what we have discussed here, your exit strategy should be in fine shape!

As a fab shop owner, you deserve to have a business that makes you money and also allows you the time to enjoy it. To find out more about how to make more money and get your life back, email me at Ed@FabricatorsCoach.com.

Reduce the Chaos | Make More Money | Get Your Life Back