Excerpt from this article originally published in the 2Q2023 Issue of the ISFA’s Countertops & Architectural Surfaces:

The stone industry has come a long way in the use of technology since I worked with my first fabrication shop client over 20 years ago. Almost every shop I visit today has some or all of the following:

- CNC saws.

- Water jet cutting.

- Digital templating.

- Robotic sawjets.

Unfortunately, the most common form of maintenance I see for this expensive equipment is a break-fix approach — we fix it after it breaks. This creates a heavy reliance on the machine manufacturer to supply parts quickly. It also creates unnecessary and costly schedule interruptions for the fabricator.

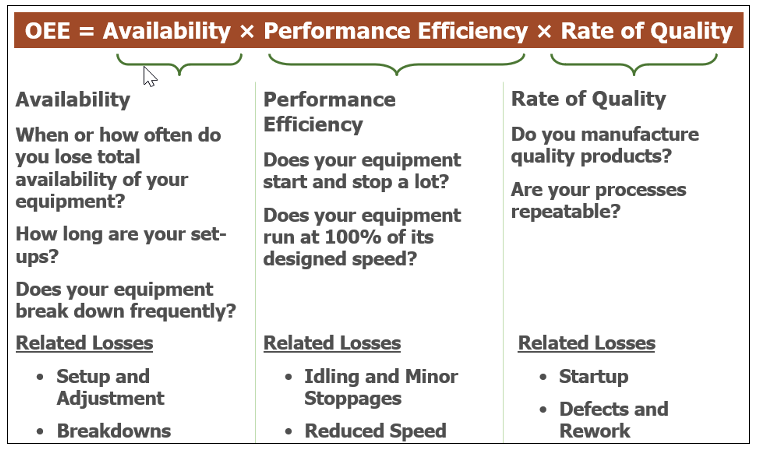

As an owner of a stone fabrication shop, planning for maintenance of this critical equipment is another key strategy to increase your fabrication shop’s profitability.

To see all the illustration and read the complete article in ISFA’s Countertops & Architectural Surfaces, you can find it here.

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www. fabricatorscoach.com or reach Ed directly at Ed@FabricatorsCoach.com or click the Schedule FREE Call button.