When I ask fabrication owners or managers: How do you improve profit? – the most common answer is: Reduce cost.

Next I ask: What costs do you try to reduce?

Answers will include:

– Negotiate a lower price for raw materials and supplies

– Keep a closer watch on how many consumables we buy

– Get my people to perform better so I can reduce my labor costs

– Determine the best capital investments

Then I ask: How much improvement in profit do you get from doing those things? Usually the answer is something like – I can cut 2-3% out of my costs. Sometimes they use a little larger number, but it rarely goes over about 5%.

Labor costs are where most managers focus, and those costs generally run 10-15% for most fabricators. If you reduce that by even an astronomical 10%, you only put 1% toward the bottom line. In addition, it is always tough to recruit and retain quality candidates – employees that your competition is always trying to steal away from you. Add to this the fact that you frequently must give out raises to keep your best people and the truth is the cost of labor is increasing rather than decreasing.

There is only so much you can do to impact your raw material cost or sales price. You can’t buy stone at a penny a slab, and you can’t sell it for $10,000 per slab, for example. The reason is the market sets these prices – supply and demand rule. So, to improve profit, in addition to the limited impact from trying to control labor costs, there is very little you can do to leverage raw material cost or sales price.

The point is: Attacking cost reduction to improve profit is simply majoring on minors – focusing on the minutia. Most owners or managers feel like they have already found the low hanging fruit and are sifting through the details of their operation like mining for pocket change in the couch cushions. It’s also the easier path to take – labor efficiency and product yield are easy to see and manage. I don’t recommend abandoning these efforts but, if this is the majority of your improvement efforts, then you are in trouble.

To make matters worse, all this is happening in an environment where the phenomenal availability of information means that your competitors are also attacking the same issues, using the same information, making similar decisions – and you are just trying to get there first.

The result is owners and managers are in a constantly chaotic struggle to make more money for their business. When I talk to managers about this, I ask: Do you feel like the guy who is charged with draining the swamp only to find yourself up to your rear end in alligators? I generally get a resounding YES. It is evident that stress levels are high.

This obsession with cost reduction is unnecessarily increasing stress and keeping you from understanding how your business really makes money.

Archimedes said: Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.

You have a process step somewhere in your business that is either where you apply your secret sauce or represents your unique strength and competitive edge. It could be a specific machine, or it could just be the spot where you apply your unique knowledge and techniques. It is usually on the plant floor. This process step is your fulcrum. I call it your constraint. It is the point around which you can leverage your business to have a greater impact than all cost reduction efforts.

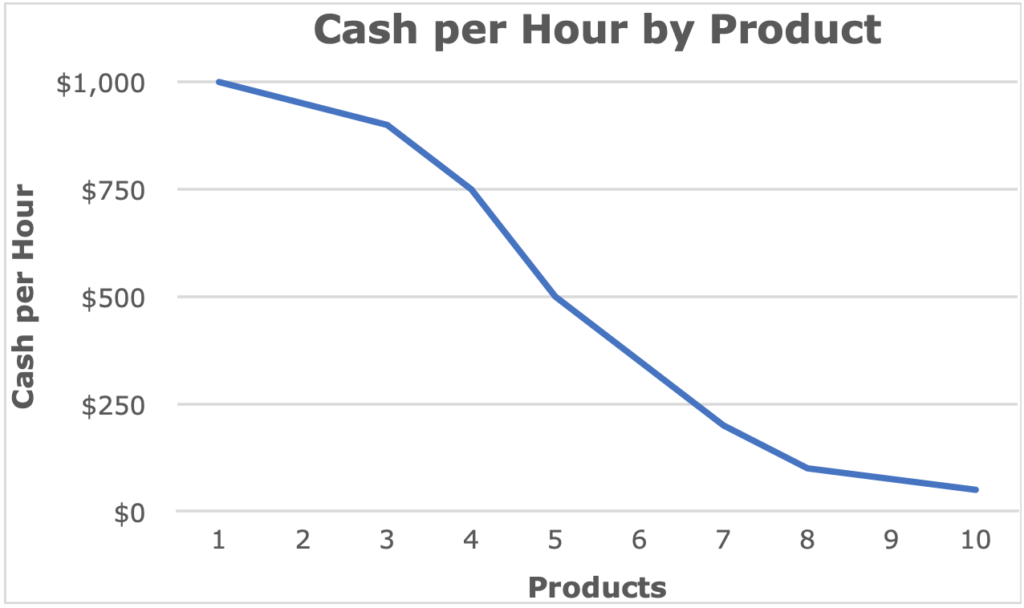

Certain types of customers make money for you faster than others. When you use the appropriate measures, you can calculate how fast each type of job generates money for your business – based on its performance at this constraint process step. More importantly, you can compare the different job types to each other to see which ones are the best and which aren’t as good.

Filling your plant with the products that make money for you faster can have a dramatic effect on profitability – many, many times greater than traditional cost reduction efforts.

As an example, if you can take a portion of the capacity consumed by the products on the right side of the graph below and fill it with products from the left side, profits begin to multiply – not just increase, but MULTIPLY.

The capacity of your plant to make products is not infinite – it has a practical limit. It is important to understand that we are talking about how to best utilize that capacity by filling it with products that make money for you the quickest.

Stop mining the couch cushions looking for pocket change and give us a call. We’ll help you set up an effective system that will give you predictability and control of your countertop business, reduce the chaos in your day, and help you become much more profitable. Ed@FabricatorsCoach.com